Ready-to-use 3D printer design seminar

Rapid prototyping seminar

Past Light Fabrication Seminars

seminar objectives

3D printers have been in the news every day since President Obama mentioned them in his State of the Union address, but it is not surprising that their high-end is optical modelling.

In this seminar, you will not learn the general theory of the optical modelling method as a new knowledge, but learn the state-of-the-art design techniques, including knowledge of the standard modelling costs, for those who design prototypes for practical use.

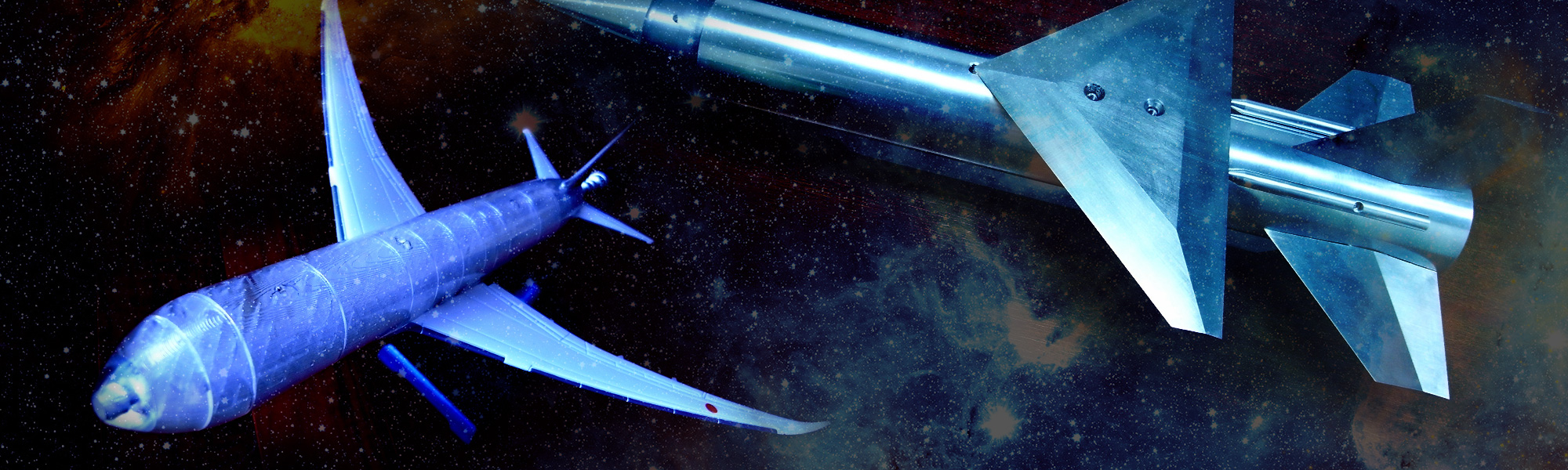

The lecturer has been at the forefront of the world in optical modelling design since the mid-1990s, when optical modelling equipment was first put to practical use, and has also worked on material modification, the results of which have been utilised to a great extent in the aerodynamic development of the HondaJet. His design achievements are among the most extensive in the world, and he will provide appropriate advice on technical issues faced by participants while introducing many actual examples.

In particular, the collection of 'NG-techniques' learned from failures will serve as a practical guideline as a very useful know-how for new product development.

It is recommended for engineers who are currently designing with optical modelling (3D printers) and have doubts about their design methods.

We can help these people

- Engineers with technical issues and an interest in optical modelling

- Measurement personnel who want to perform visualisation and pressure distribution measurements with new test methods.

- Structural designers considering lightweight, high-strength structural materials.

- Production engineering personnel who want to carry out a wide variety of prototypes in a short period of time.

- Engineers and researchers who have doubts about the practicality of light modelling.

- Researchers considering experimental equipment that makes use of the design freedom of optical fabrication.

- Engineers who are currently dealing with optical modelling design and want to broaden their practical skills.

Lecturers.

Hideo Shigetani

He worked for 25 years at Honda Research Institute, where he was stationed in the USA and developed a business jet prototype, before becoming project leader for the HondaJet, responsible for wind tunnel testing and overall flight testing.

Since 1996, optical modelling has been incorporated into wind tunnel testing in earnest, and tests have been carried out by JAXA, NASA and others.

In 2009, he set up Tokyo Ryuken Corporation, which received orders to develop fluid-related equipment from JAXA, Shimizu Corporation, NTT Environment Lab and others.

Representative: Hideo SHIGETANI

Representative: Hideo SHIGETANI

Seminar dates

Day 1 (29 Jul 2013) - State-of-the-art 3D printers & optical design know-how -.

- The power of 3D printers & optical fabrication (from the sponsors)

- Areas of technology for which 3D printers & optical modelling are suitable

Comparison of characteristics with metals by concrete examples (accuracy, strength weight). - Material selection guidelines

Suitability for requirements such as transparency, strength and heat resistance - Design methods to reduce costs

- Methods of increasing strength and rigidity.

- Heat resistance considerations

- Technology useful as an experimental model.

Multipoint pressure measurement, visualisation, sensor mounting etc. - Notes on post-processing

- Designed for support removal.

- Cleaning and storage methods

- Minimising deformation over time and repair methods.

Day 2 (30 Jul 2013) - Create 3D data and try modelling -.

.

- data conversion

- Data checking points

- How to request a moulding manufacturer

- Indication of materials used and stacking direction

- Estimated costs and delivery times/li>.

.

- Witnessing during moulding

- Checking the finished state of the dough

- Importance of the finishing process in determining the degree of perfection.

- Key points for completion inspections

- Transport notes.