Work performed 2017

Work performed 2017

2017.

-

-

-

- Dec.

-

- JAXA Space Research Institute Honeycomb structure component for reusable rocket experimental vehicle (metal 3D printing) Delivery

- Delivery of engine thrust mounts for reusable rocket experimental vehicles to JAXA Space Research Institute, etc.

-

- November.

-

- Aerodynamic drag reduction device (photo-fabricated) for wind tunnel testing delivered to JAXA Aeronautics Division.

- JAXA Aeronautics Division Joint patent application for pressure belt, etc.

-

- Oct.

-

- Tottori University Delivery of wing models for wind tunnel testing.

- Delivery of engine fan simulator test equipment to JAXA's Aeronautics Division, etc.

-

- September.

-

- Delivery of a wind test model (made by optical moulding) with specifications for measuring static and unsteady pressure for low-speed wind tunnel tests, Tohoku University.

- Nikkan Kogyo Shimbun newspaper coverage of new design applications for 3D printing and metal modelling, etc.

-

- August.

-

- Kyushu University, delivery of light-fabricated low-speed wind tunnel test model.

- Surface hardening trials and evaluation for light fabrication materials, etc.

-

- July.

-

- JAXA Aerospace Research Laboratory Delivery of aerodynamic measurement devices for the experimental aircraft 'Flyby'.

- JAXA Aerospace Research Laboratory Successful bidding and production promotion of engine fan simulator prototypes, etc.

-

- June.

-

- JAXA Space Research Institute (JAXA) Study on manufacturing and quality control of large structural components for spacecraft.

- Investigation of space mechanics adaptation of topology design and analysis by metal modelling, etc.

-

- May.

-

- JAXA Space Research Institute, meeting on new manufacturing methods for spacecraft.

- Study of surface treatment methods for metal-formed products and evaluation of prototypes, etc.

-

- April.

-

- JAXA Aerospace Research Laboratory Inspection of photo-fabricated aerodynamic devices after flight tests at Komaki Airport.

- Investigation and prototyping of the integration of non-stationary pressure sensors into optical fabrication devices, etc.

-

- Mar.

-

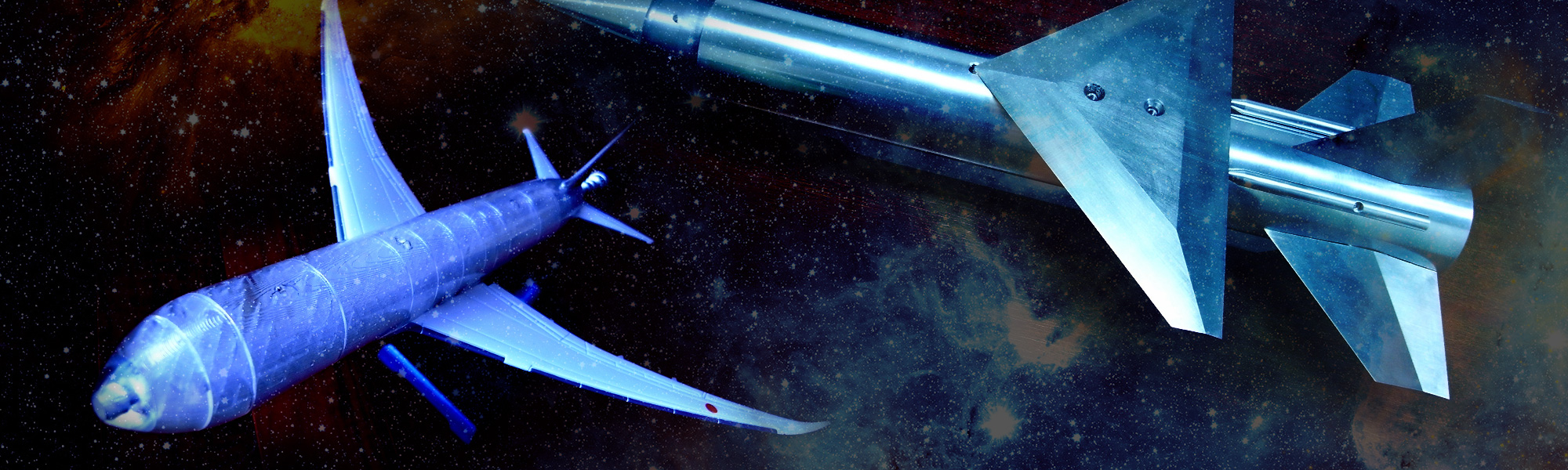

- Reusable rocket-style test model (all-metal and light modelling) for JAXA Space Research Institute Delivery

- JAXA Space Research Institute Delivery of a multi-point pressure measurement model made by optical modelling for low-speed wind trials.

- M Heavy Industries, 2 all-metal models for supersonic wind trials, delivered.

- Delivery of photo-fabricated fans and stators to JAXA Aerospace Research Laboratory, etc.

-

- February

-

- JAXA Aerospace Research Laboratory Delivery of a 3D printed honeycomb-structured aircraft hull model for actual aircraft testing.

- Attendance at Osaka Civil Aviation Bureau for application for permission to fly test actual aircraft.

- Installation of multi-point pressure measurement equipment on JAXA's experimental aircraft Flight at Komaki Airport.

- JAXA Space Research Institute Delivery of a 2D wing model for multi-point pressure measurement made by optical moulding, etc.

-

- Jan.

-

- JAXA Aerospace Research Laboratory Delivery of metal 3D printed fan blade components

- JAXA Space Research Institute and I Heavy Industries, meeting on the production of observation rockets.

- M Heavy Industries Request for review of all-metal semi-cut wind trial model.

- Production and strength testing of 3D printed large honeycomb panels, etc.

-

-